-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

High Capacity Manual Chain Hoist

High quality manual hand chain block and tackle available upto 50 tonne as standard and 100 tonne on request.

MCHT-3654

These manual chain hoists are manufactured with the leading design concept and available capacities ranging from 30000kg to 50000kg as standard but are available up to 100 tonnes upon request.

The MCHT chain hoist is a resulting factor from the application of high technology with emphasis on overall performance required in a quality chain hoist.

With lighter weight, higher efficiency and more compact size, these hoists are valuable in a wide variety of lifting applications. This successful design derives from the development of the smallest yet ultra-strong link load chain. Unparalleled in the world, manufactured to the highest quality the load chains on the MCHT hoists have an unbelievable breaking strength of 1,000N/mm2 (100kgf/mm2).

Due to the superior quality and performance, we are confident that the chain hoist will fulfil all the end-user's needs because of the following important features.

Alongside our high-capacity chain block range, we also offer many other makes and models from the world's leading manufacturers, starting from capacity options as low as 125kg.

Durable and Reliable!!

The high-class load chain with a breaking strength of 1000N/mm2 (100kgf/mm2) constitutes the main factor for reliable and safe operation. Also, a dry type of braking mechanism provides excellent performance. This means these models are designed for the hardest work, in the toughest conditions.

10 Key Features

Gear Case and Hand Wheel Cover Resistant to External Shocks

Both sides of the hoist are covered with a thick steel gear case, processed with the highest level technology and with a strengthened wheel cover. They have an ideal shape and rigidity to maintain bearing alignment and withstand external shocks.

Double Enclosure to Keep Out Rainwater and Dust

The braking mechanism, which makes up the heart of the hoist, is enclosed in a double cover: the wheel and the brake covers. These protective covers not only keep out weather elements but also help to prevent mud and dust from entering internal mechanisms. Hand chain guide attached to the wheel cover provides durability and smooth operation of a hand chain on a hand chain wheel.

Double Pawl Spring Mechanism to Further Increase Sureness

In case one of the pawl springs is damaged, the other maintains its functions. This mechanism further increases sureness and safety.

Sure and Reliable Mechanical Brake

A dry-type asbestos-free Mechanical Brake ensures strong brake performance, endurance and reliability.

Hooks for Easy Work

Specially heat-treated top and bottom hooks have enough strength and toughness for the hardest jobs. The design of the bottom hook, with relatively large dimensions, makes it easy to stabilize a load in the proper position. The bottom Yoke features a guard protecting the chain pin & nut from damage which again enhances safety.

Bearing Mechanism to Increase Mechanical Efficiency

The use of unique ball and needle bearings remarkably increases mechanical efficiency and produces high output power with minimum manual input.

Load Chain Guide Mechanism

Chain guide mechanism in flanged load sheave and guide roller facilitate smooth movement of the load chain.

Highly Accurate and Durable Gears

Compact but highly efficient and durable gears to ensure the utmost accuracy.

Stopper Prevents Excessive Lowering

Stopper assembly prevents excessive lowering of a load and also keeps the load chain from exiting if over-lowered (lowered too quickly). When you feel a noticeable increase in pull force to lower the load, you may realize that you cannot lower the load any further.

Ultra Strong Load Chain (Nickel plated)

Load chains, the component comprising the heart of the chain hoist, are made of an exclusively developed, heat-treated special steel alloy. Carefully selected special steel is entirely processed at fully automated production facilities under the most stringent quality control procedures. Thus, all of the chains are uniform in high breaking stress of 1000N/mm2(100kgf/mm2). They have excellent quality including toughness and resistance to wear and corrosion.

Corrosion Resistant Nickel Diffused Chain

We recommend chain hoists with ND (Nickel Diffused) chain, for outstanding corrosion resistance and use at work sites under the strong influences of rainwater, seawater, vapour or chemicals, etc. Since the ND chains are manufactured by giving a unique osmotic- diffusion treatment to special metals with unique technology, they have extremely strong corrosion resistance. Also, there is no peeling off of the plating. Clients are requested to consult with the nearest distributor before use of these chains because their corrosion-resistant efficiency differs, depending upon which chemicals are or may be in the surrounding area or environment.

As standard these manual hoists are available in capacities of 30 tonne, 40 tonne or 50 tonnes, however, even larger capacity chain hoists up to 100t (100 tonnes) are available upon request.

Overload Protection Device (OLL)

The hoist with an overload limiter protects the hoist mechanism from damage due to overloading. When an overload is applied to the hoist, the overload limiter actuates to stop lifting.

Technical Specifications

| Rated Load (W.L.L.) | Model | Std Lift (m) | Hand Chain Folded Length (m) | Chain Pull to Lift Full Load (N) [kgf] | Chain Overhaul to Lift Load One Metre (m) | Load Chain Dia. x Chain Falls |

Test Load |

Net Weight (kg) | Approx Shipping Weight (kg) | Weight per Additional Metre of Lift (kg) |

| 30 tonne | MCHT30 | 3.5 | 4.5 | 421 [43] x2 | 495 x 2 | 9mm x 10 | 40t | 310 | 400 | 19.2 |

| 40 tonne | MCHT40 | 3.5 | 4.5 | 421 [43] x2 | 693 x 2 | 9mm x 14 | 50t | 480 | 630 | 26.2 |

| 50 tonne | MCHT50 | 3.5 | 4.5 | 480 [49] x2 | 792 x 2 | 9mm x 16 | 62.5t | 640 | 790 | 29.7 |

- Other capacities are available upon request.

- Any lift of chain is available upon request.

- As the chains are heat treated, splicing of the load chain is prohibited.

- When ordering, specify lifting height.

- Chain Falls varies on each capacity.

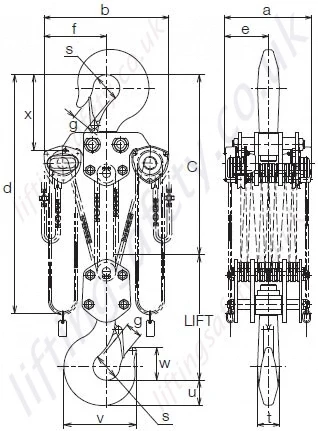

Dimensional Information

| Rated Load (W.L.L.) |

Model | Headroom C (mm) | Dimensions (mm) | |||||||||||

| a | b | d | e | f | g | s | t | u | v | w | x | |||

| 30t |

MCHT30 | 1300 | 404 | 746 | 4800 | 202 | 373 | 103 | 125 | 85 | 112 | 367 | 143 | 400 |

| 40t |

MCHT40 | 1480 | 502 | 760 | 4900 | 251 | 380 | 96 | 145 | 123 | 133 | 412.5 | 182.5 | 445 |

| 50t |

MCHT50 | 1560 | 544 | 796 | 4900 | 272 | 398 | 100 | 165 | 135 | 155 | 447.5 | 202.5 | 467 |

|

| 30000kg, 40000kg and 50000kg Dimensional Drawing |

Pricing

These manual chain hoists are manufactured with the leading design concept and available capacities ranging from 30000kg to 50000kg as standard but are available up to 100 tonnes upon request.

The MCHT chain hoist is a resulting factor from the application of high technology with emphasis on overall performance required in a quality chain hoist.

With lighter weight, higher efficiency and more compact size, these hoists are valuable in a wide variety of lifting applications. This successful design derives from the development of the smallest yet ultra-strong link load chain. Unparalleled in the world, manufactured to the highest quality the load chains on the MCHT hoists have an unbelievable breaking strength of 1,000N/mm2 (100kgf/mm2).

Due to the superior quality and performance, we are confident that the chain hoist will fulfil all the end-user's needs because of the following important features.

Alongside our high-capacity chain block range, we also offer many other makes and models from the world's leading manufacturers, starting from capacity options as low as 125kg.

Durable and Reliable!!

The high-class load chain with a breaking strength of 1000N/mm2 (100kgf/mm2) constitutes the main factor for reliable and safe operation. Also, a dry type of braking mechanism provides excellent performance. This means these models are designed for the hardest work, in the toughest conditions.

10 Key Features

Gear Case and Hand Wheel Cover Resistant to External Shocks

Both sides of the hoist are covered with a thick steel gear case, processed with the highest level technology and with a strengthened wheel cover. They have an ideal shape and rigidity to maintain bearing alignment and withstand external shocks.

Double Enclosure to Keep Out Rainwater and Dust

The braking mechanism, which makes up the heart of the hoist, is enclosed in a double cover: the wheel and the brake covers. These protective covers not only keep out weather elements but also help to prevent mud and dust from entering internal mechanisms. Hand chain guide attached to the wheel cover provides durability and smooth operation of a hand chain on a hand chain wheel.

Double Pawl Spring Mechanism to Further Increase Sureness

In case one of the pawl springs is damaged, the other maintains its functions. This mechanism further increases sureness and safety.

Sure and Reliable Mechanical Brake

A dry-type asbestos-free Mechanical Brake ensures strong brake performance, endurance and reliability.

Hooks for Easy Work

Specially heat-treated top and bottom hooks have enough strength and toughness for the hardest jobs. The design of the bottom hook, with relatively large dimensions, makes it easy to stabilize a load in the proper position. The bottom Yoke features a guard protecting the chain pin & nut from damage which again enhances safety.

Bearing Mechanism to Increase Mechanical Efficiency

The use of unique ball and needle bearings remarkably increases mechanical efficiency and produces high output power with minimum manual input.

Load Chain Guide Mechanism

Chain guide mechanism in flanged load sheave and guide roller facilitate smooth movement of the load chain.

Highly Accurate and Durable Gears

Compact but highly efficient and durable gears to ensure the utmost accuracy.

Stopper Prevents Excessive Lowering

Stopper assembly prevents excessive lowering of a load and also keeps the load chain from exiting if over-lowered (lowered too quickly). When you feel a noticeable increase in pull force to lower the load, you may realize that you cannot lower the load any further.

Ultra Strong Load Chain (Nickel plated)

Load chains, the component comprising the heart of the chain hoist, are made of an exclusively developed, heat-treated special steel alloy. Carefully selected special steel is entirely processed at fully automated production facilities under the most stringent quality control procedures. Thus, all of the chains are uniform in high breaking stress of 1000N/mm2(100kgf/mm2). They have excellent quality including toughness and resistance to wear and corrosion.

Corrosion Resistant Nickel Diffused Chain

We recommend chain hoists with ND (Nickel Diffused) chain, for outstanding corrosion resistance and use at work sites under the strong influences of rainwater, seawater, vapour or chemicals, etc. Since the ND chains are manufactured by giving a unique osmotic- diffusion treatment to special metals with unique technology, they have extremely strong corrosion resistance. Also, there is no peeling off of the plating. Clients are requested to consult with the nearest distributor before use of these chains because their corrosion-resistant efficiency differs, depending upon which chemicals are or may be in the surrounding area or environment.

As standard these manual hoists are available in capacities of 30 tonne, 40 tonne or 50 tonnes, however, even larger capacity chain hoists up to 100t (100 tonnes) are available upon request.

Overload Protection Device (OLL)

The hoist with an overload limiter protects the hoist mechanism from damage due to overloading. When an overload is applied to the hoist, the overload limiter actuates to stop lifting.

Technical Specifications

| Rated Load (W.L.L.) | Model | Std Lift (m) | Hand Chain Folded Length (m) | Chain Pull to Lift Full Load (N) [kgf] | Chain Overhaul to Lift Load One Metre (m) | Load Chain Dia. x Chain Falls |

Test Load |

Net Weight (kg) | Approx Shipping Weight (kg) | Weight per Additional Metre of Lift (kg) |

| 30 tonne | MCHT30 | 3.5 | 4.5 | 421 [43] x2 | 495 x 2 | 9mm x 10 | 40t | 310 | 400 | 19.2 |

| 40 tonne | MCHT40 | 3.5 | 4.5 | 421 [43] x2 | 693 x 2 | 9mm x 14 | 50t | 480 | 630 | 26.2 |

| 50 tonne | MCHT50 | 3.5 | 4.5 | 480 [49] x2 | 792 x 2 | 9mm x 16 | 62.5t | 640 | 790 | 29.7 |

- Other capacities are available upon request.

- Any lift of chain is available upon request.

- As the chains are heat treated, splicing of the load chain is prohibited.

- When ordering, specify lifting height.

- Chain Falls varies on each capacity.

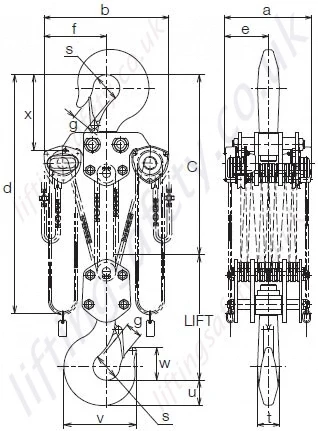

Dimensional Information

| Rated Load (W.L.L.) |

Model | Headroom C (mm) | Dimensions (mm) | |||||||||||

| a | b | d | e | f | g | s | t | u | v | w | x | |||

| 30t |

MCHT30 | 1300 | 404 | 746 | 4800 | 202 | 373 | 103 | 125 | 85 | 112 | 367 | 143 | 400 |

| 40t |

MCHT40 | 1480 | 502 | 760 | 4900 | 251 | 380 | 96 | 145 | 123 | 133 | 412.5 | 182.5 | 445 |

| 50t |

MCHT50 | 1560 | 544 | 796 | 4900 | 272 | 398 | 100 | 165 | 135 | 155 | 447.5 | 202.5 | 467 |

|

| 30000kg, 40000kg and 50000kg Dimensional Drawing |

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.